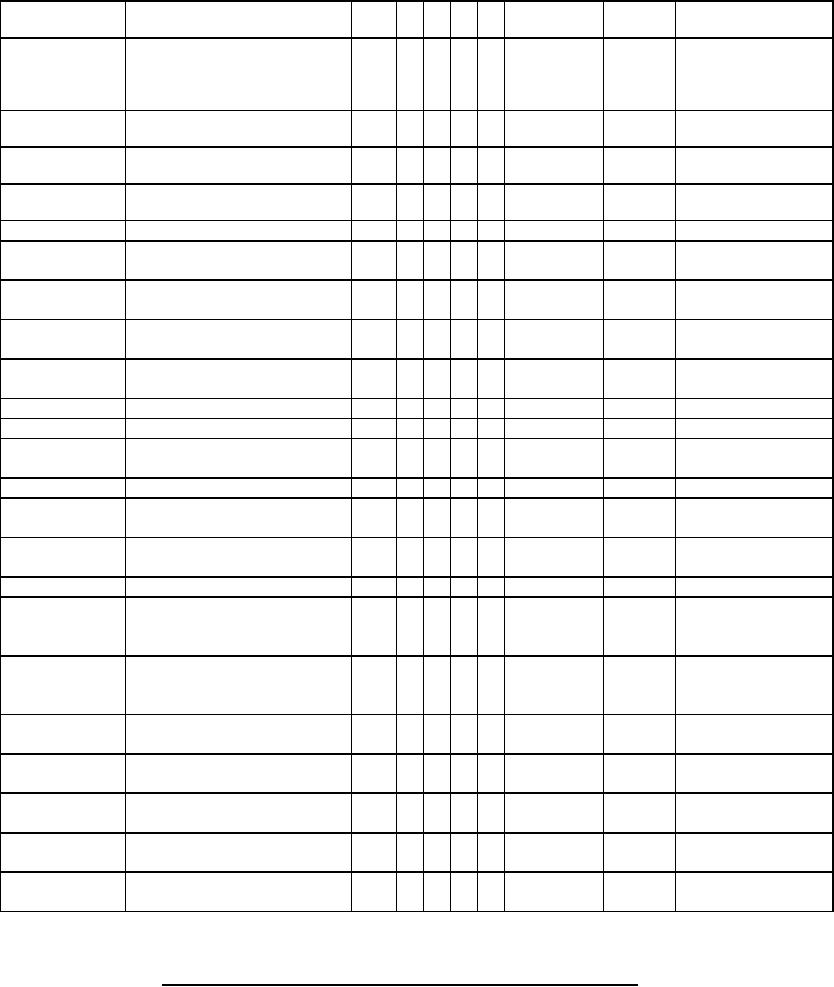

MIL-DTL-45195F (AR)

Cartridge case with

XX

X

X

4.3.2.9

3.2.9

propelling charge

Projectile and

XX

X

X

4.3.2.10

3.2.10

cartridge case

assemblies (prior

to pack)

Unsealed fiber

XX

X

X

4.3.2.11

3.2.11

container

Sealed fiber

XX

X

X

4.3.2.12

3.2.12

container

Sealed wood

XX

X

X

4.3.2.13

3.2.13

packaging box

3.2.14

Ballistic test

XX

X

X

4.3.2.14

3.3

Ammunition lot

X

X

X

4.3.1

numbering

3.4.1

Interior cavity

XX

X

X

4.3.2.1

metal defects

3.4.2

Unsolidified pool

XX

X

X

4.3.2.1

of paint.

3.4.3

Projectile cavity

XX

X

X

4.3.2.1

contamination

3.4.4

Interior coating

XX

X

X

4.3.2.1

3.4.5

Solid explosive

XX

X

X

4.3.2.1

3.5.1-

Radiographic

XX

X

X

4.3.2.2/4.4.3

3.5.8

Inspection

3.6

Mating surfaces

XX

X

X

4.3.2.3

3.7

Fuze well surface

XX

X

X

4.3.2.3

cavitation

3.8

Base separation saw

XX

X

X

4.3.2.3/4.4.1

samples

3.9

Fuze well (before)

XX

X

X

4.3.2.3

3.10

Fuze well (after

XX

X

X

4.3.2.4

assembly of the

liner)

3.11

Exterior surfaces

XX

X

X

4.3.2.4

explosive

contamination

Metal parts breakup

3.12.1

X

X

X

4.3.2.14/

4.4.2

Shearing of

X

X

X

4.3.2.14/

3.12.2

rotating band

4.4.2

Rotating band

X

X

X

4.3.2.14/

3.12.3

failure

4.4.2

3.12.4

Muzzle velocity

X

X

X

4.3.2.14/

4.4.2/4.4.2.1

3.13

Workmanship

X

X

X

4.3.2.1 thru

4.3.2.13

TABLE II. Requirement/Verification Cross Reference Matrix- Continued

13

For Parts Inquires submit RFQ to Parts Hangar, Inc.

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business