MIL-DTL-48360A (AR)

parts and assemblies listed in 3.2 and the conduct of all test specified in Table II and when

required Table III (see 6.10).

4.2.3 First article rejection. If any item fails to comply with requirements, the first article

sample shall be rejected.

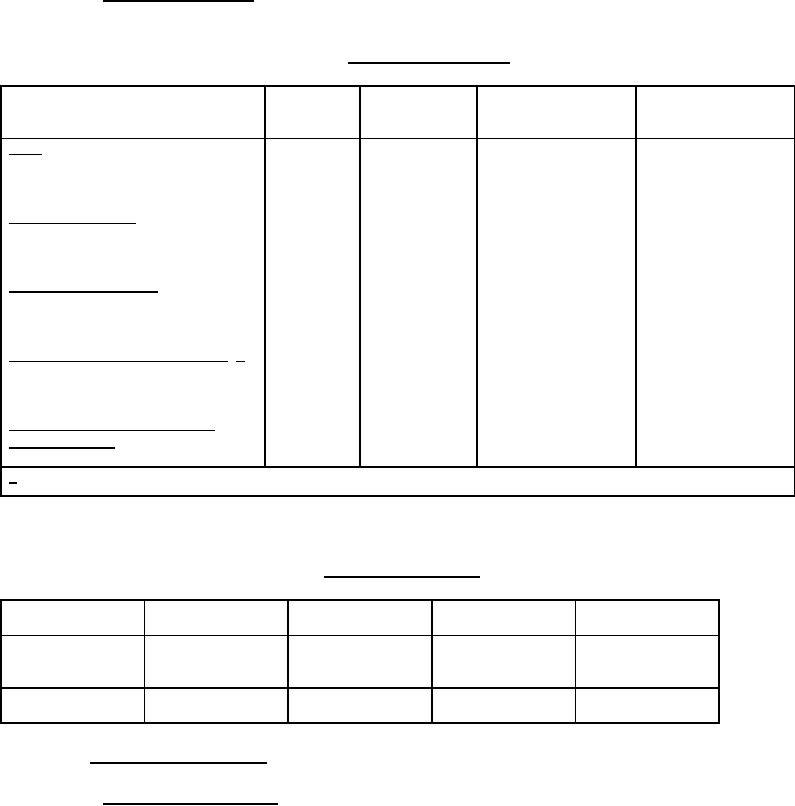

TABLE II. First article inspection.

Number of

Requirement

Inspection Method

Sample

Examination or Test

Conformance Criteria

Paragraph

Reference

Units

Body

15

3.2.1

4.3.2.1

100%

(Dwg. 9281867)

Examination of defects

Laminated lead cloth

15

3.2.2

4.3.2.2

100%

(Dwg. 12913756)

Examination of defects

Body and liner assembly

15

3.2.3

4.3.2.3

100%

(Dwg. 9282044)

Examination of defects

15

3.2.4

4.3.2.4

Charge, propelling, M200, assembly (1/)

100%

(Dwg. 9282042)

Examination of defects

100%

3.2

4.4.2.1

Propellant weight from assembled

100%

propelling charge

1/ Propellant charge assemblies shall be packed in a fiber drum.

The following test program should be used for the initial production test:

TABLE III. Initial production test.

Temperature

No. Test

TECOM

Test Phase

No. Control Rounds

(Deg F)

Rounds

TOP

Propellant

70

10

TOP-4-2-504

Checkout

145

10

TOP-4-2-504

-60

10

TOP-4-2-504

Sequential

145

15

60

TOP-4-2-504

Environmental

-60

15

60

TOP-4-2-504

4.3 Conformance inspection.

4.3.1 Inspection lot formation. Inspection lots shall comply with the lot formation

provisions of MIL-STD-1916 and lot numbering shall comply with MIL-STD-1168. In addition,

inspection lots of propellant shall contain M30 propellant, Type I, from not more than one lot

from one manufacturer. An entire lot of propellant shall be utilized in the formation of one lot of

propelling charges unless otherwise specified in the contract.

6

For Parts Inquires submit RFQ to Parts Hangar, Inc.

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business